Custom Timing Pulleys For Manufacturers

Common Components We Build for the Manufacturing Industry

At Illinois Pulley & Gear, all of the common components that we offer are fully customized with your business in mind. We don't start with a part and hope that it meets your requirements. We take the time to learn as much as possible about who you are and what you're trying to accomplish — with that background, we create and execute a plan that will exceed your expectations each and every time.

Customized Parts

Just a few of the customized parts that we're capable of producing at Illinois Pulley & Gear include but are not limited to ones like timing pulley stock, pulley replacement parts, and flanges.

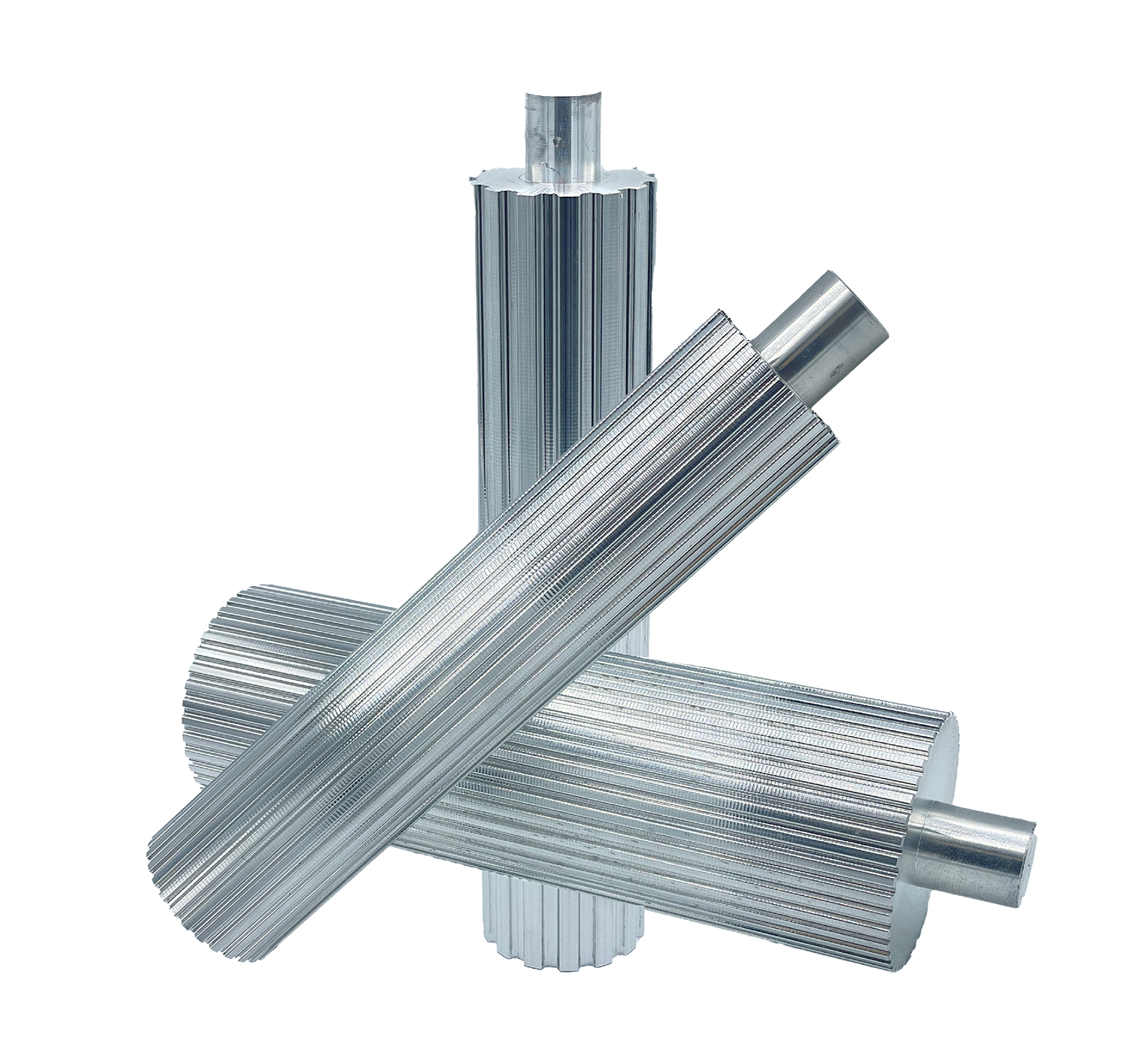

Timing Pulley Stock

Illinois Pulley & Gear is capable of manufacturing a wide range of high-quality timing pulley stock, all of which is manufactured on demand. This puts us in an ideal position to successfully produce what is essentially an unlimited variety — all of which has been fully customized to meet your precise specifications.

All you need to do is select the material you want to work with, specify the tooth profile you need, and any number of teeth you have in mind. We'll take care of the rest.

Indeed, once we understand your specific needs, we have all that is necessary to come up with the types of innovative solutions you can depend on. We pride ourselves on our fast turnaround times because we know that manufacturers have specific schedules. We'll have whatever you need in your hands not in months or weeks, but literally in a matter of days.

Flanges

Illinois Pulley & Gear has spent years developing and honing an innovative flanging process — one that is designed to produce the highest quality products in all circumstances. All told, we employ one of a few different methods depending on the requirements of the project. These include ones like:

- Roll staking. This is a technique commonly used when a flange needs to be attached to a smaller timing pulley. A crimp is produced around the entirety of the flange, securing everything in place.

- Heat shrinking. Here, the flange itself will be heated to 450 degrees, after which it is moved into place. As it is allowed to cool, it shrinks to the perfect size to hold things tightly.

- Bolt-on flanges. This is a process employed with some of the heaviest and most rugged flanges you're likely to encounter. The flange is held securely with flat-head screws, which are also easy to remove should maintenance be required.

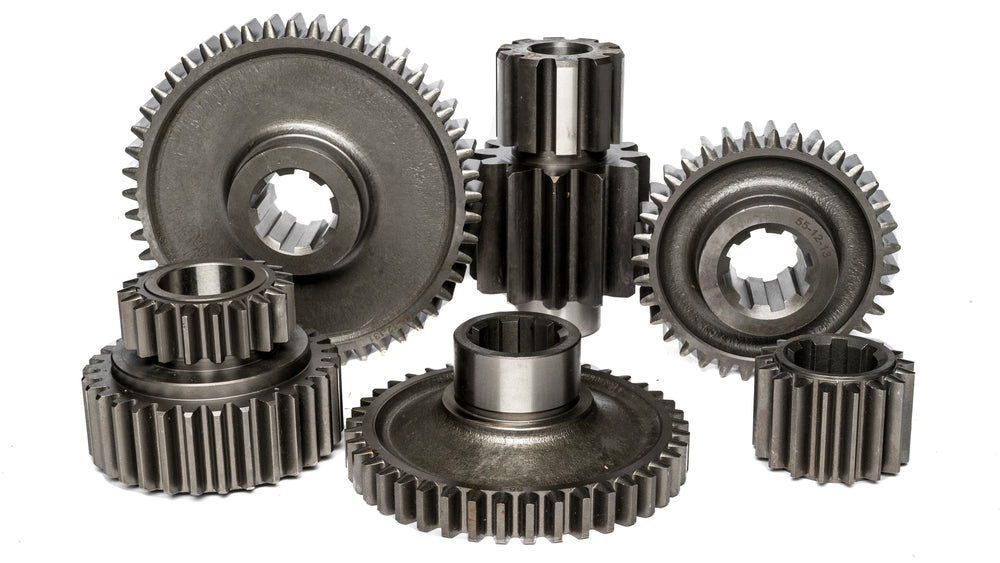

Pulley Replacement Parts

Another type of common component that we offer for manufacturers has to do with pulley replacement parts. Sometimes, finding the right replacement parts can be an uphill battle. Maybe the original manufacturer has long since gone out of business, and now this critical piece of machinery that your business literally depends on is unsupported. Perhaps you've lost the original manual, so you're not quite sure what you're dealing with in the first place.

Thankfully, it doesn't matter — we've gone out of our way to design a process for pulley replacement parts that is as simple as you need it to be. Even if all you have to work from is the part itself, all you need to do is send it to us. We can reverse-engineer it within a matter of days to make sure that unexpected (and not to mention costly) periods of downtime are a thing you don't have to worry about ever again.

We work with many different materials in any tooth profile that you require. In addition to aluminum, we also offer steel, stainless steel, and plastics like nylon and Delrin.

At Illinois Pulley and Gear, we're prepared to help you understand the intricacies of each option so that you pick the one that is best for your specific needs.

Get In Touch with IPG Today!

All of our manufacturing clients know that they can trust the team at Illinois Pulley & Gear to get the job done properly. If necessary, our team can even drive to your location and take a look at exactly what you need — all so that we can get to work on recreating it before you deal with issues like equipment failure and downtime.

All the while, we'll be communicating with our customers every step of the way — offering you the type of uncompromising service that you simply won't find anywhere else.

If you'd like to find out more information about our custom timing pulleys or other components that we regularly create for our manufacturing customers, or if you have any additional questions you'd like to go over with someone in a bit more detail, please contact the team at Illinois Pulley & Gear today.

CUSTOMER TESTIMONIALS

ILLINOIS PULLEY & GEAR HAS PROVIDED PRECISION MACHINING SERVICES FOR US FOR OVER 5 YEARS. THEY HAVE BEEN CONSISTENTLY RELIABLE, PROFESSIONAL, AND FLEXIBLE FROM QUOTING TO MANUFACTURING AND DELIVERY.

PROJECT MANAGER, TECHNICO PRECISION MANUFACTURING, INC.

ILLINOIS PULLEY AND GEAR HAS BEEN AMAZING TO WORK WITH. THEY PRODUCE HIGH-QUALITY, CUSTOM PARTS, AND THEY KNOW THEIR BUSINESS.

PROJECT MANAGER

Need Help?

We’re Here For You!

Searching for gear manufacturers near you? All IPG pulley stock is precision machined from bar stock at our Schaumburg facility. We do not use extrusions or imported pulley stock. Pick your material, tooth profile, and any number of teeth and we will produce it.

Find us at our location or contact us via phone or email:

Illinois Pulley & Gear

611 Lunt Ave. Unit C

Schaumburg IL, 60193

847-407-9595

sales@ipgbiz.com