Gear Hobbing

At IPG, we specialize in the precision manufacturing of gears using advanced gear hobbing techniques. Our modern gear hobbing machines allow us to produce high-quality gears that meet the exacting standards of our clients.

Gear hobbing is a versatile and widely used process for creating gears. It involves using a specialized cutting tool called a hob to cut teeth into a gear blank. The hob rotates and moves along the gear blank, cutting teeth into the metal as it rotates.

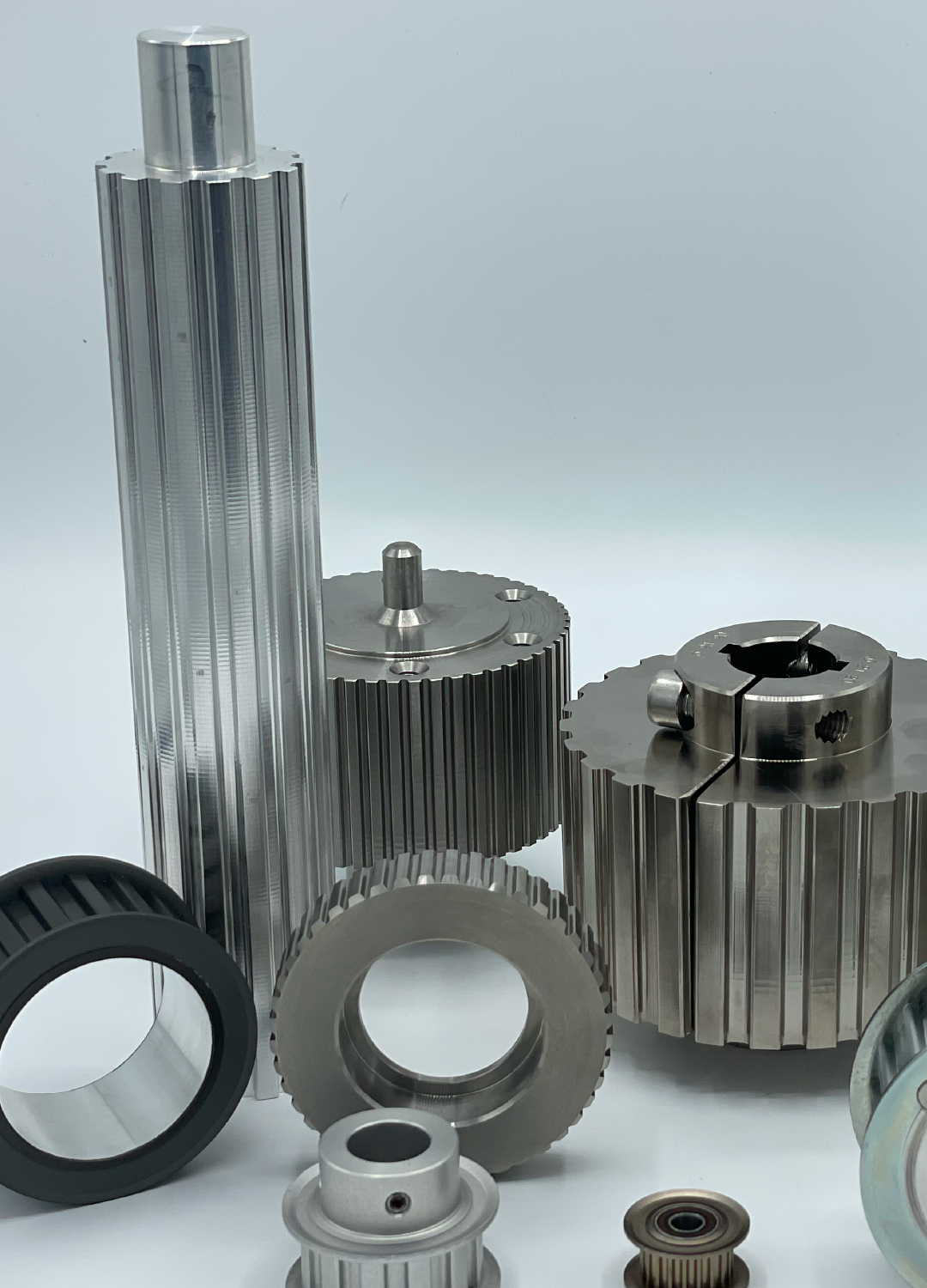

Our gear hobbing process is designed to produce a wide variety of gears, including:

-

Spur Gears: Simple, straight-toothed gears used in many applications.

-

Helical Gears: Gears with angled teeth, providing smoother and quieter operation.

-

Splines: Longitudinal grooves used for transmitting torque.

Product Summary

Made-to-order timing pulleys may be produced from a variety of materials including:

Aluminum – Grades 6061, 2024, and 7075

Stainless Steel – Grades 303, 304, 316, and 17-4

Steel – Grades 1018, 1215, 1144, 1045 and 4140

Plastics – Nylon, Delrin

We offer timing pulleys in any tooth profile. Since our pulleys are made-to-order, pulleys can be made with any possible number of teeth or bore size, English or Metric.

Product Summary

AVAILABLE PICTHES

Our timing pulley boasts a toothed wheel that ensures a seamless interaction with timing belts or chains, guaranteeing an impeccably coordinated movement of rotating shafts. What sets our pulley apart is its commitment to maintaining precise timing, a critical factor in various applications. From engines to conveyor systems, printers, and beyond, our timing pulley plays a pivotal role in achieving consistent and reliable performance.

REQUEST A QUOTE

Ready to upgrade your equipment's performance with high-quality pulley replacement parts? Request a quote today, and our team will provide you with competitive pricing and expert guidance to ensure your machinery runs smoothly and efficiently.

WHY CHOOSE IPG?

Having over 120 years of combined experience in this industry allows us to continue to grow and manufacture solutions for your needs.

As a precision machined component manufacturer, our goal is to provide the finest quality products to our customers and to do so more efficiently and economically. By satisfying our customers’ needs, we will ensure they will continue to do business with us and recommend us to others.

Our core values are honesty, trust, hard work, responsibility, going beyond what is expected, fairness, taking pride in our work, personal growth, career growth and helpfulness.

CUSTOMER TESTIMONIALS

ILLINOIS PULLEY & GEAR HAS PROVIDED PRECISION MACHINING SERVICES FOR US FOR OVER 5 YEARS. THEY HAVE BEEN CONSISTENTLY RELIABLE, PROFESSIONAL, AND FLEXIBLE FROM QUOTING TO MANUFACTURING AND DELIVERY.

PROJECT MANAGER, TECHNICO PRECISION MANUFACTURING, INC.

ILLINOIS PULLEY AND GEAR HAS BEEN AMAZING TO WORK WITH. THEY PRODUCE HIGH-QUALITY, CUSTOM PARTS, AND THEY KNOW THEIR BUSINESS.

PROJECT MANAGER

Need Help?

We’re Here For You!

Searching for gear manufacturers near you? All IPG pulley stock is precision machined from bar stock at our Schaumburg facility. We do not use extrusions or imported pulley stock. Pick your material, tooth profile, and any number of teeth and we will produce it.

Find us at our location or contact us via phone or email:

IPG

618 Lunt Ave. Unit C

Schaumburg IL, 60193

847-407-9595

sales@ipgbiz.com