Flanging Process

ILLINOIS PULLEY & GEAR, INC MANUFACTURES HIGH PRECISION COMPONENTS.

At Illinois Pulley & Gear, our flanging process is unique. Each of our flanging methods promise the highest quality product. We know that pulley motion cannot stop – inopportune pulley failure can cause significant damage to machinery.

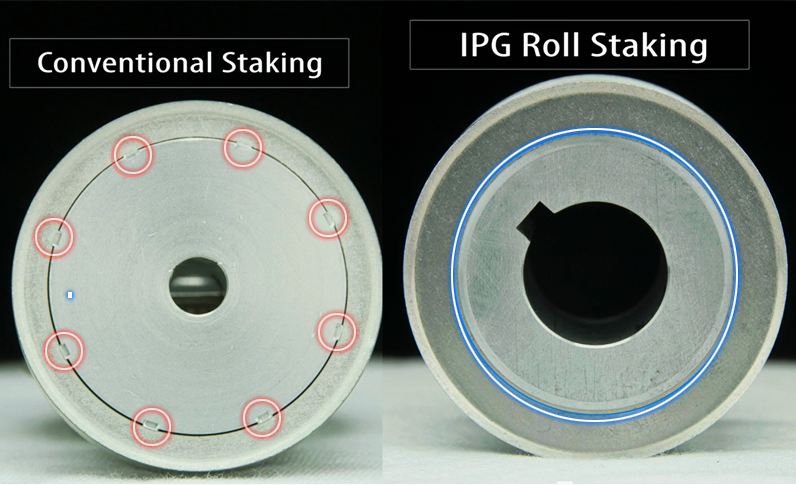

Roll Staking

Roll staking is an excellent way of attaching flanges to smaller timing pulleys. Roll staking produces a crimp 100% of the way around the edge of the flange, rather than on 6 to 8 points. This method is superior to conventional staking methods that only hold a small percentage of the flange to the pulley.

HEAT SHRINKING

Heat shrinking is an exceptional way of attaching heavy, large-diameter flanges to timing pulleys. The flanges are heated to 450 degrees Fahrenheit or more and then placed onto the pulleys’ flange step, which is 0.015” to 0.020” larger in diameter than the ID of the flange in its cold state. Upon cooling, the flange shrinks onto the flange step of the pulley, permanently holding it in place.

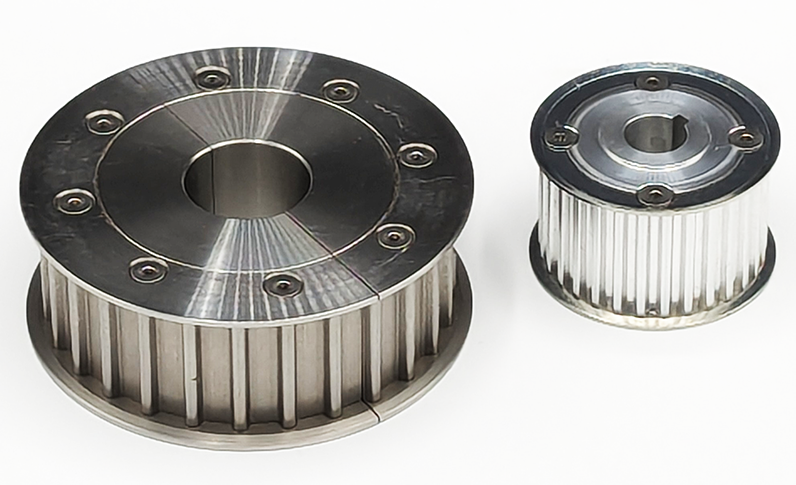

BOLT-ON FLANGES

For the ultimate option, IPG makes bolt-on flanges – the heaviest and most durable flanges available. Flanges are held to the sides of the timing pulleys by flat head screws. An additional advantage to bolt-on flanges is the ability to remove the flange for belt maintenance. Other flanging methods do not allow flange removal for maintenance purposes.

WHY CHOOSE ILLINOIS PULLEY & GEAR?

Having over 90 years of combined experience in this industry allows us to continue to grow and manufacture solutions for your needs.

As a custom timing pulley manufacturer, our goal is to provide the finest quality products to our customers and to do so more efficiently and economically. By satisfying our customers’ needs, we will ensure they will continue to do business with us and recommend us to others.

Our core values are honesty, trust, hard work, responsibility, going beyond what is expected, fairness, taking pride in our work, personal growth, career growth and helpfulness.

CUSTOMER TESTIMONIALS

ILLINOIS PULLEY & GEAR HAS PROVIDED PRECISION MACHINING SERVICES FOR US FOR OVER 5 YEARS. THEY HAVE BEEN CONSISTENTLY RELIABLE, PROFESSIONAL, AND FLEXIBLE FROM QUOTING TO MANUFACTURING AND DELIVERY.

PROJECT MANAGER, TECHNICO PRECISION MANUFACTURING, INC.

ILLINOIS PULLEY AND GEAR HAS BEEN AMAZING TO WORK WITH. THEY PRODUCE HIGH-QUALITY, CUSTOM PARTS, AND THEY KNOW THEIR BUSINESS.

PROJECT MANAGER

Need Help?

We’re Here For You!

Searching for gear manufacturers near you? All IPG pulley stock is precision machined from bar stock at our Schaumburg facility. We do not use extrusions or imported pulley stock. Pick your material, tooth profile, and any number of teeth and we will produce it.

Find us at our location or contact us via phone or email:

Illinois Pulley & Gear

611 Lunt Ave. Unit C

Schaumburg IL, 60193

847-407-9595

sales@ipgbiz.com