Power Transmission Parts

COMMON COMPONENTS WE BUILD FOR POWER TRANSMISSION EQUIPMENT

The team at Illinois Pulley & Gear has worked hard over the years to earn our reputation as a leading provider of components that are tailor-made with power transmission equipment in mind.

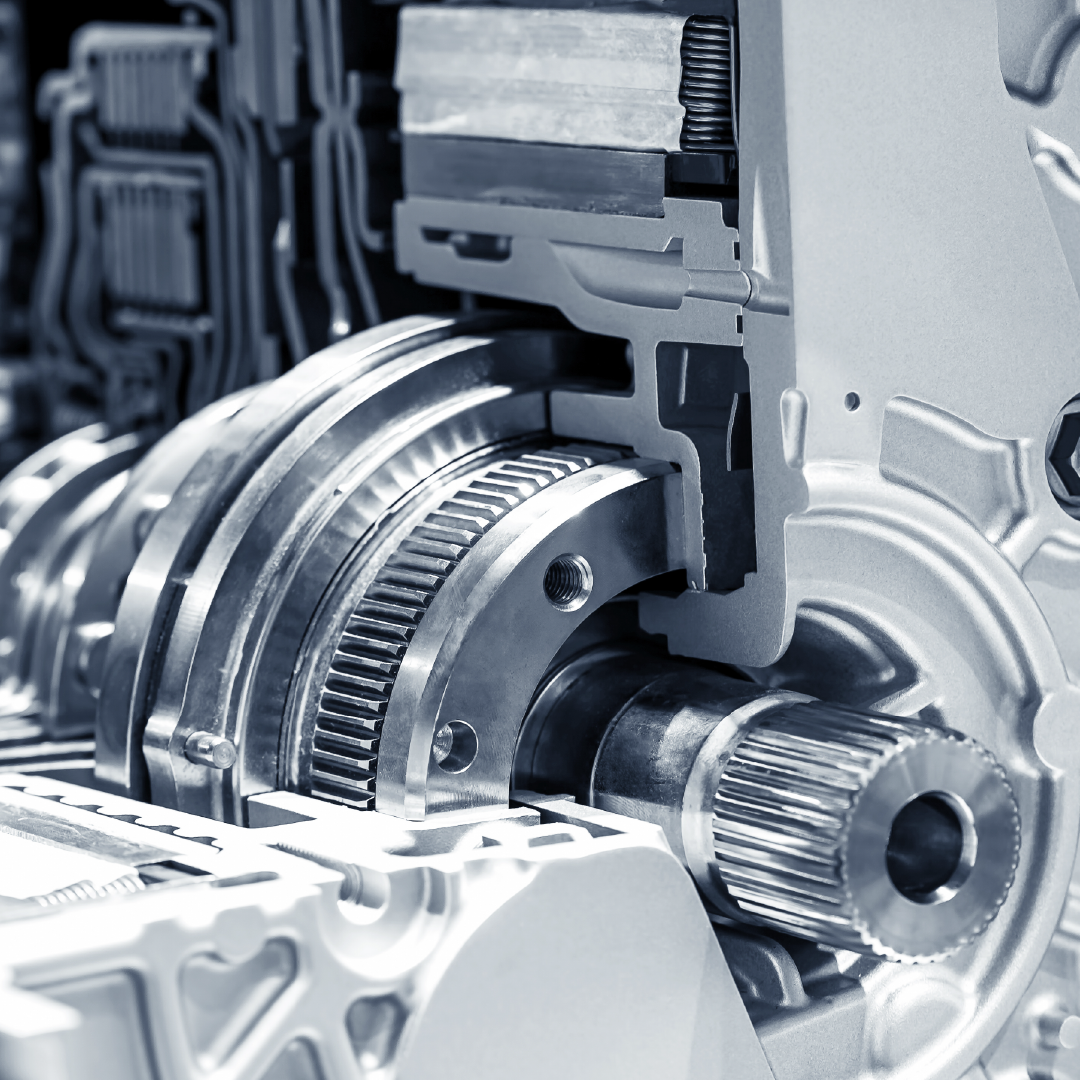

HOW ARE POWER TRANSMISSIONS STRUCTURED?

Just a few of the common components that we’re capable of manufacturing include:

- Timing Belts

- Timing Pulley Stock

- Pulley Replacement Parts

- Flanges

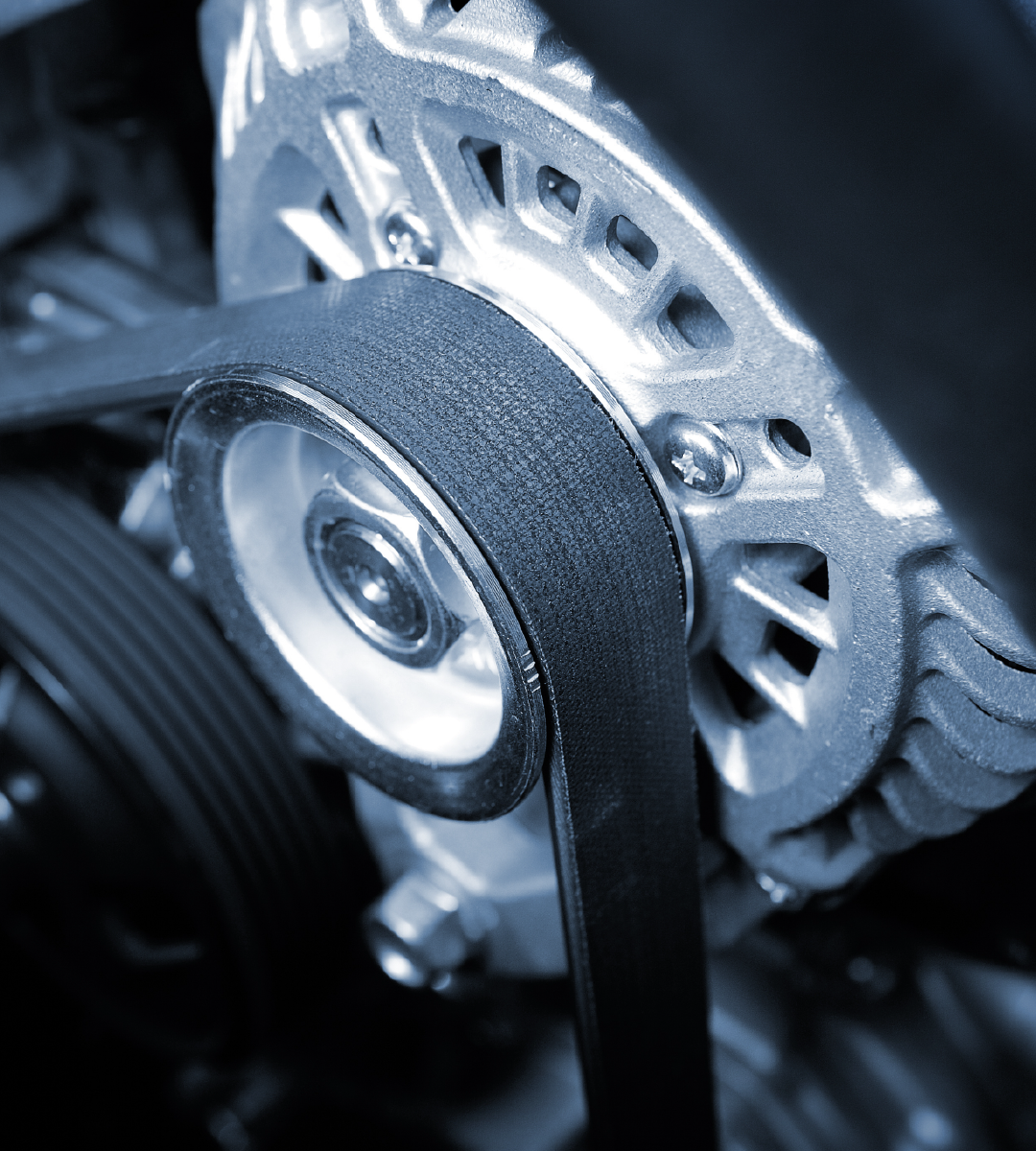

TIMING BELTS

The goal of any timing belt is simple: you’re trying to create a synchronous, non-slip transmission of movement during the manufacturing process. You can’t do this if your timing belt and your timing belt pulley aren’t working together, which is always our top priority.

Illinois Pulley & Gear can produce timing belts that are made-to-order with any material or pitch that you need. From the moment we opened our doors until now, we’ve always pledged to listen to and comprehend your specialized requirements, providing you with the innovative solutions you need to thrive in your own business. Not only do we want to do this as efficiently as possible, but in the most cost-effective way as well.

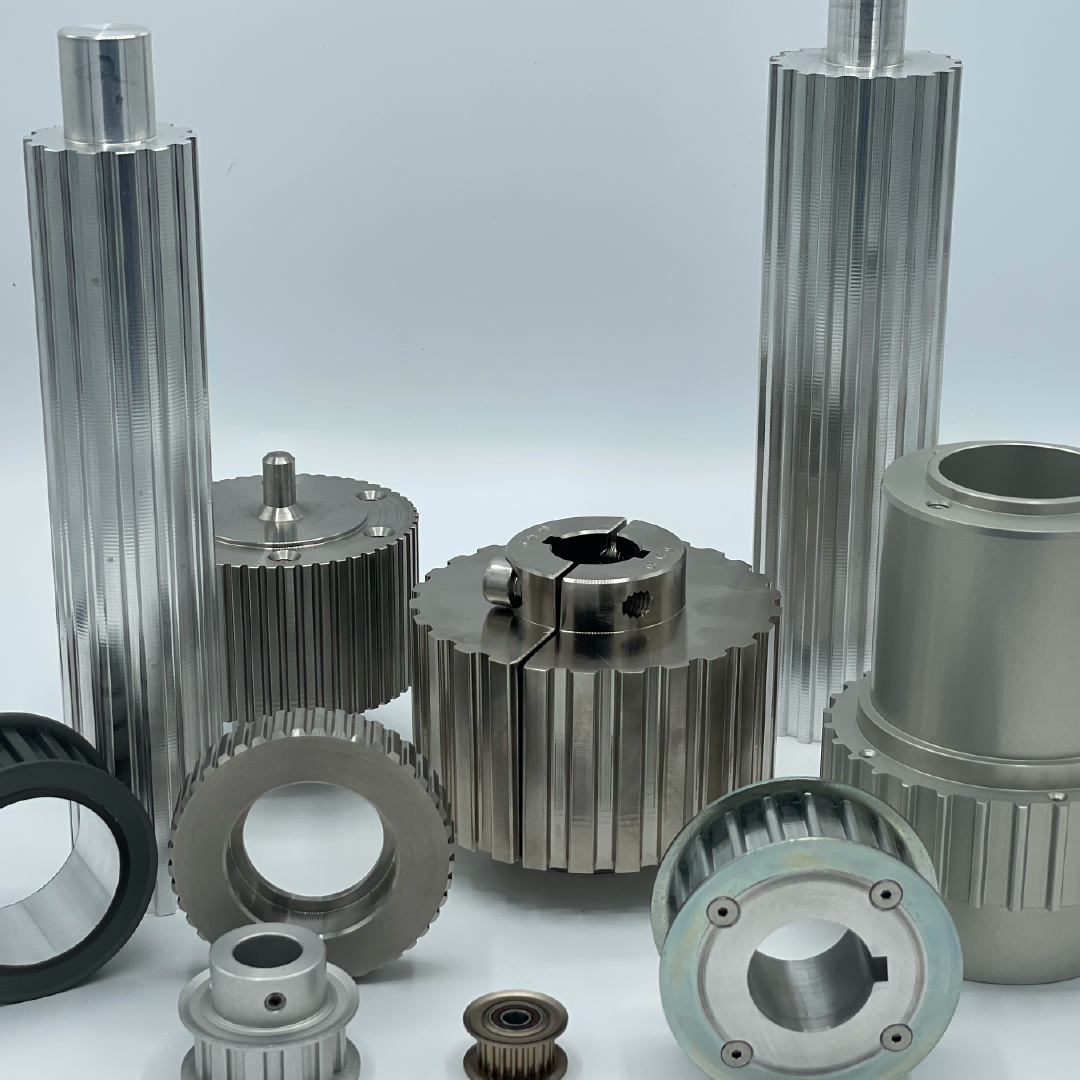

TIMING PULLEY STOCK

As is true with every other custom part that we manufacture, all the timing pulley stock that comes from Illinois Pulley & Gear comes straight from our Schaumburg factory. In addition to supporting our local economy, we find that the added benefit of keeping our operations localized exclusively in the United States is that we can be actively involved at all parts of the process. Not only that, but it allows us to offer the fast turnaround times our clients need when they run into troubles of any kind.

Because of this, you also have complete control over the final shape of your finished product. Once we know what it is that you’re trying to accomplish, all you have to do is specify the type of material you want to use and the number of teeth you need. We can take care of the rest and have timing pulley stock in your hands before you know it.

Even if you’re working with a rare or otherwise unique type of material, or if you’re trying to do something that you’ve been historically unable to, we have what it takes to make the impossible a reality. We’re fast, we’re flexible, and we’re as precise as you need us to be – exactly the way it should be.

PULLEY REPLACEMENT PARTS

A lot of organizations don’t realize just how difficult it can be to find pulley replacement parts until it’s too late.

Pulleys work for a long time with regular maintenance but when the time does come for a replacement, you could be looking at a situation where the original equipment manufacturer (OEM) has gone out of business. That company isn’t around to support a machine that you’ve already invested heavily in over the years. Sometimes, the part itself was rare from the start and finding a suitable replacement seems like an uphill battle.

Thankfully, the team at Illinois Pulley & Gear is here to help. Rather than dealing with periods of costly and unexpected equipment downtime, we can have you back up and running again as soon as possible. Even if you don’t have your machine’s original documentation or you don’t know the precise part you’re looking for, don’t worry. You can send us what you have, and we’ll reverse engineer it. At that point, you won’t need to worry about finding a suitable replacement ever again because you know that you can always have one in a matter of not months or weeks, but days.

The Illinois Pulley & Gear team can work with just about any type of material you need in any tooth profile you want, including ones like:

Aluminum — Stainless Steel — Steel — Plastics like Nylon or Delrin

FLANGES

Something we’ve always been proud of at IPG is our industry leading flanging process – one that we developed ourselves through hard work and dedication. We take advantage of a few different techniques to help meet your demands, regardless of what they may be.

Roll skating, for example, sees a flange attached to a smaller timing pulley in a way that is always easily maintainable. Heat shrinking, on the other hand, is ideal when you need to attach large, heavy flanges to timing pulleys. This is a bit more permanent, as the material gets heated to 450 degrees before being secured into place.

When it comes to power transmissions in particular, our bolt-on flanges are also a common option for many clients. This is one of the most durable methods available and sees flanges held in place on the sides of a timing pulley by flat head screws. The key advantage of this is that those screws can be easily removed by just about anyone during the maintenance process. This is also why this is one of the more common methods being used by various companies for the purposes of prototyping and experimentation in particular.

WHY CHOOSE ILLINOIS PULLEY AND GEAR?

At Illinois Pulley & Gear, we pride ourselves on being more than just another service provider. In addition to providing you with the kinds of gears, pulleys, and timing belts for power transmission that you can depend on, we also want to go one step further and offer you an exceptional experience in any sense of the term. One that is custom-built with your needs in min and that you won’t be able to find anywhere else.

Truly, we want to act as a partner – one that is just as invested in your success as you are and who will proudly stand by your side, regardless of the challenges you face. We’ll come up with the right solution together.

If you’re interested in finding out more about the gears, pulleys, and timing belts that we’re capable of manufacturing for power transmissions, or if you’d just like to get started on your next big project but aren’t sure where to begin, please don’t hesitate to contact the team at Illinois Pulley & Gear today.

CUSTOMER TESTIMONIALS

ILLINOIS PULLEY & GEAR HAS PROVIDED PRECISION MACHINING SERVICES FOR US FOR OVER 5 YEARS. THEY HAVE BEEN CONSISTENTLY RELIABLE, PROFESSIONAL, AND FLEXIBLE FROM QUOTING TO MANUFACTURING AND DELIVERY.

PROJECT MANAGER, TECHNICO PRECISION MANUFACTURING, INC.

ILLINOIS PULLEY AND GEAR HAS BEEN AMAZING TO WORK WITH. THEY PRODUCE HIGH-QUALITY, CUSTOM PARTS, AND THEY KNOW THEIR BUSINESS.

PROJECT MANAGER

Need Help?

We’re Here For You!

Searching for gear manufacturers near you? All IPG pulley stock is precision machined from bar stock at our Schaumburg facility. We do not use extrusions or imported pulley stock. Pick your material, tooth profile, and any number of teeth and we will produce it.

Find us at our location or contact us via phone or email:

Illinois Pulley & Gear

611 Lunt Ave. Unit C

Schaumburg IL, 60193

847-407-9595

sales@ipgbiz.com