Packaging and Labeling

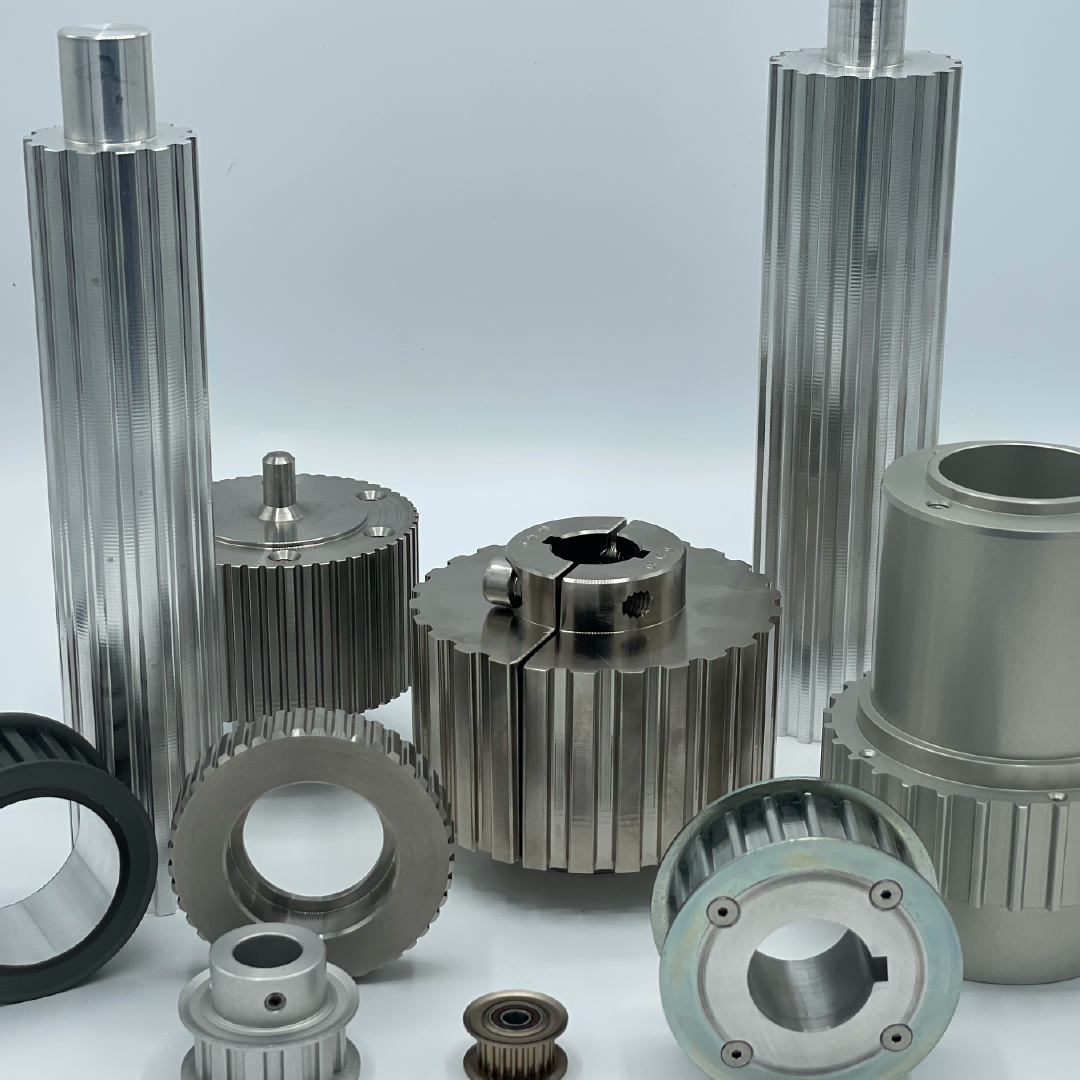

COMMON COMPONENTS WE BUILD FOR PACKAGING AND LABELING EQUIPMENT

At Illinois Pulley & Gear, we understand that your business needs equipment that it can depend on in order to operate efficiently. This is especially true when it comes to packaging machines, as you’re talking about a situation where literally every second counts.

You can’t afford to deal with poorly maintained machines that aren’t operating at peak efficiency, or equipment that constantly (and unexpectedly) goes offline due to the same issues cropping up again and again. The team at IPG doesn’t want to see that happen to you, which is why we manufacture a wide range of common components for packaging and labeling equipment for you to choose from depending on your needs.

Just a few examples of the common components we offer include but are not limited to ones like:

- Timing belts.

- Timing pulley stock.

- Pulley replacement parts.

- Flanges.

- And more.

TIMING PULLEYS

At Illinois Pulley & Gear, all of our timing pulleys are made-to-order, all to your precise specifications. You only need to tell us what your requirements are in terms of things like pitch, the total number of teeth, bore size, keyway, setscrews, lightening holes, and timing marks. We’ll be able to take care of the rest.

We also regularly work with customers who are searching for timing pulleys for a specific need but just aren’t sure where to begin. This is in service of making sure you always have the assets you can depend on in the most cost-effective way possible.

TIMING PULLEY STOCK

Illinois Pulley & Gear also manufactures custom timing pulley stock, right here in the United States at our facility in Schaumburg. We don’t use extrusions, and we don’t import stock from elsewhere in the world. By keeping everything at home and under our control, we can eliminate a lot of the risks that many often deal with in more complicated jobs.

Keeping everything in Schaumburg also gives us the freedom we need to match your requirements, regardless of how complicated they might be. Our clients know that they can come to us with specifications like tooth profile, the number of teeth, and others, and we’ll take care of the rest. They even know that we’ll help them choose the right material based on whatever the end application happens to be.

PULLEY REPLACEMENT PARTS

One of the great things about pulleys in general is that they’re durable pieces of equipment. If properly maintained, they can last for years. Unfortunately, this means that by the time you do need pulley replacement parts, finding the right ones can often be a challenge to say the least.

Sometimes, the part you need is routinely out of stock, regardless of how many providers you try. Sometimes, it’s been so long since that pulley was originally purchased that it is no longer supported by the original equipment manufacturer – meaning that replacement parts simply are not an option.

Regardless, it’s important for you to know that the team at Illinois Pulley & Gear is here to help. Even if you don’t have the original owner’s manual for the machine (meaning that you’re not quite sure what part you need in the first place), that’s okay. We can take what you do have and reverse engineer it, getting your equipment back up and running again as quickly as possible. Likewise, thanks to our aforementioned Schaumburg facility, we can do this as quickly as possible. Not in months or even weeks, but often in a matter of days.

In addition to creating pulley replacement parts for packaging and labeling equipment, we also have first-hand experience in a range of other industries so be sure to inquire about your options when you call.

FLANGES

Since our inception, Illinois Pulley & Gear has worked hard to develop a unique flanging process that allows us to create better quality products for our customers far faster and more cost-effectively than ever before. Depending on the situation we use a combination of different techniques like:

· Roll staking, which is something that we do as opposed to crimping just a few points around the edge of the flange. Typically, roll staking results in a crimp of 100%.

· Heat shrinking. This is when the flange is heated to a minimum of 450 degrees, at which point it is then placed on the flange step and allowed to cool. As it does, it will shrink onto the pulley so that it is then permanently held in place.

· Bolt-on flanges. These are often necessary when you’re in need of heavy, durable flanges. The flange is attached to the timing pulley via flat-head screws. The major benefit of this is that if you need to perform maintenance in the future and remove the flange, you can do so easily.

Which of these methods is best will vary largely depending on your needs, but don’t worry – we’ll go over all of this with you before your project begins.

WHY CHOOSE IPG?

Illinois Pulley & Gear is proud of the reputation we’ve been able to earn over the years as a leading provider of timing pulleys for packaging machines, labeling equipment, and other assets. We’ve been able to get to this point because we’re a customer-focused company first and foremost. We never try to force services or solutions on you that you don’t need. Instead, we take the time to learn as much as we can about what you’re trying to accomplish. Then, armed with as much actionable information as we can gather, we set out to meet your needs and exceed your expectations each and every time we have the opportunity to do so.

It’s a level of care and attention-to-detail that most people can’t find anywhere else.

If you’d like to find out more information about timing belts for packaging machines, or if you have a big project coming up and need a partner you can trust to see it through to completion, please don’t hesitate to contact IPG today.

CUSTOMER TESTIMONIALS

ILLINOIS PULLEY & GEAR HAS PROVIDED PRECISION MACHINING SERVICES FOR US FOR OVER 5 YEARS. THEY HAVE BEEN CONSISTENTLY RELIABLE, PROFESSIONAL, AND FLEXIBLE FROM QUOTING TO MANUFACTURING AND DELIVERY.

PROJECT MANAGER, TECHNICO PRECISION MANUFACTURING, INC.

ILLINOIS PULLEY AND GEAR HAS BEEN AMAZING TO WORK WITH. THEY PRODUCE HIGH-QUALITY, CUSTOM PARTS, AND THEY KNOW THEIR BUSINESS.

PROJECT MANAGER

Need Help?

We’re Here For You!

Searching for gear manufacturers near you? All IPG pulley stock is precision machined from bar stock at our Schaumburg facility. We do not use extrusions or imported pulley stock. Pick your material, tooth profile, and any number of teeth and we will produce it.

Find us at our location or contact us via phone or email:

Illinois Pulley & Gear

611 Lunt Ave. Unit C

Schaumburg IL, 60193

847-407-9595

sales@ipgbiz.com