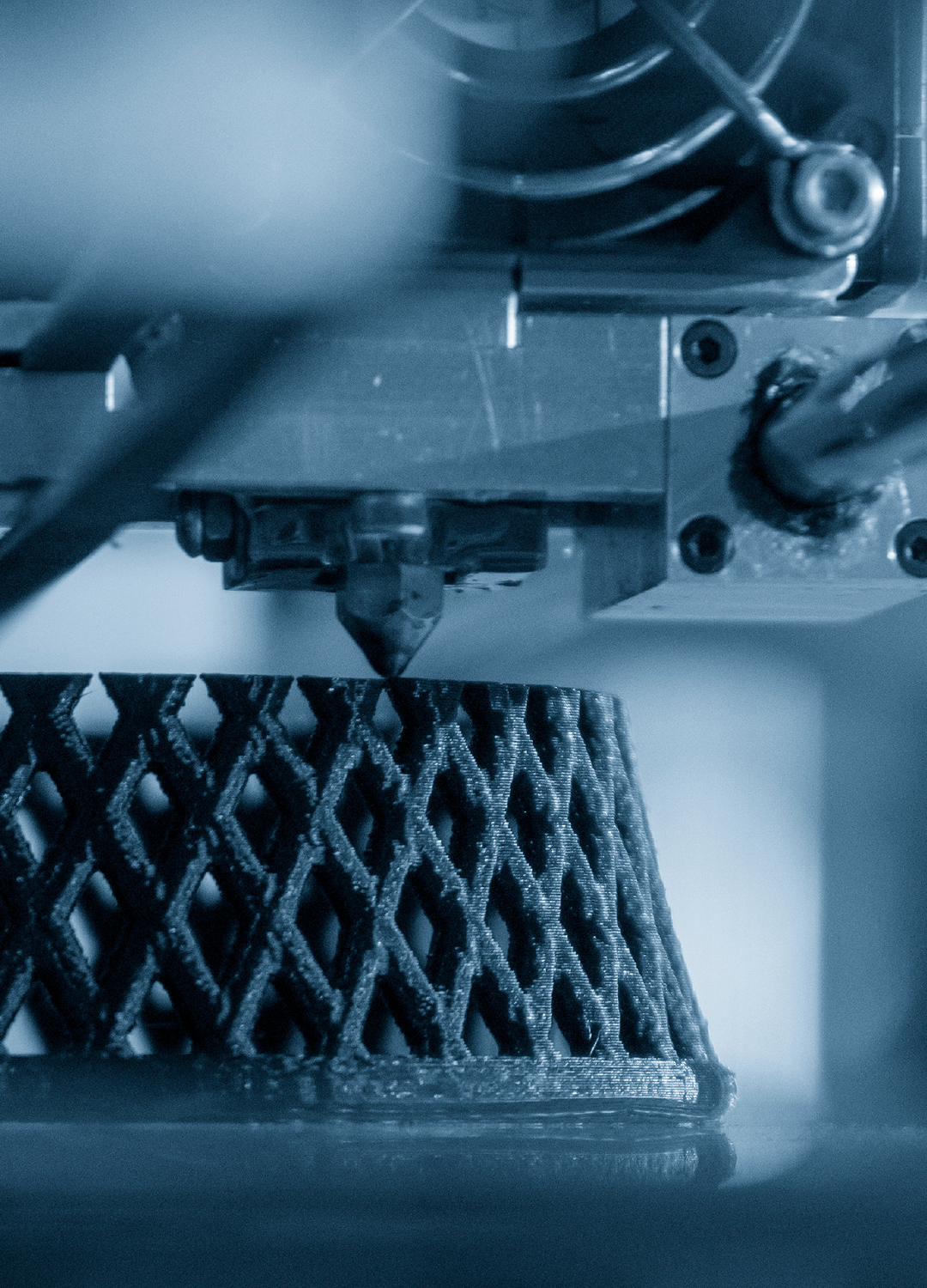

3D Printing

HIGH QUALITY, CUSTOM MADE PARTS FOR ALL YOUR 3D PRINTING NEEDS IS ONE OF ILLINOIS PULLEY & GEAR’S SPECIALTIES.

WE OFFER PRECISION AND COMPLETE CUSTOMIZABILITY AT EVERY TURN OF THE MANUFACTURING PROCESS TO ENSURE YOUR 3D PRINTERS ARE WORKING AT OPTIMAL EFFICIENCY AND CREATE THE HIGHEST QUALITY OF PRINTED PRODUCTS.

With our precision-made 3D printer components, you will be able to improve and expedite your processing methods while simultaneously mitigating downtime for your team and your equipment. Additionally, well-made 3D printers can also give your team more creative freedom, saving them both labor costs and time throughout the design and fabrication process.

IPG DIFFERENTIATORS

3D PRINTER COMPONENTS WE MANUFACTURE:

EXTRUDER DRIVE GEARS

This gear is used to grab the filament used for printing, pushing it down through what is known as the “hot end” of the 3D printer.

IDLER GEARS

Idler gears and the spring-loaded wheels which push the filament up against the extruder drive gear. These components can be perfectly manufactured to ensure that the filament is not squeezed by the gear either too forcefully or too softly.

TIMING BELTS

Using pulleys, the x and y motors will drive the belts during use. Over time, these components can begin to wear and need to be replaced.

Our team can also assist you in the design and manufacturing of:

- Pulleys & Gears for Stepper Motors

- Frame Brackets

INDUSTRIES CURRENTLY USING 3D PRINTING

Engineers of many aerospace industry leaders have begun to rely on 3D printed inspection tooling in order to reduce costs for low-volume parts that keep their planes up and running. The fabricated components must be built to withstand both extreme temperatures and harsh chemicals. Our 3D printer components are designed to be just as tough.

From racing teams to sub manufacturers, many in the auto industry are turning to 3D printers for a wide range of applications. Most commonly, printers are used for the tooling and fixtures that assist manufacturers in their processes. The most common parts fabricated are fixtures, cradles, and prototypes that require high strength and durability. Interestingly, 3D printers have even been used to fabricate replacement parts which can no longer be found for the oldest of vehicles.

Manufacturing companies of all sizes are completely changing the way they do business through the use of 3D printers. By providing the ability to create custom, low-volume tooling and fixtures at a fraction of the price, 3D printers give your designers and engineers more time to spend on the creation of revenue-generating parts.

Robotics engineers are also benefitting from the use of 3D printing to design and fabricate complex parts with a fraction of the weight and cost of more traditional components. Typically used for the creation of end-of-arm tooling and end-use parts, 3D printers ensure robotics can move faster and carry heavier loads for expedited processes.

Students and teachers of every level, from middle school to PhD programs are using 3D printers for a variety of educational purposes. Illinois Pulley and Gear has the ability to ensure your educational technology continues to operate smoothly for the benefit of many generations of students to come.

CUSTOMER TESTIMONIALS

ILLINOIS PULLEY & GEAR HAS PROVIDED PRECISION MACHINING SERVICES FOR US FOR OVER 5 YEARS. THEY HAVE BEEN CONSISTENTLY RELIABLE, PROFESSIONAL, AND FLEXIBLE FROM QUOTING TO MANUFACTURING AND DELIVERY.

PROJECT MANAGER, TECHNICO PRECISION MANUFACTURING, INC.

ILLINOIS PULLEY AND GEAR HAS BEEN AMAZING TO WORK WITH. THEY PRODUCE HIGH-QUALITY, CUSTOM PARTS, AND THEY KNOW THEIR BUSINESS.

PROJECT MANAGER

Need Help?

We’re Here For You!

Searching for gear manufacturers near you? All IPG pulley stock is precision machined from bar stock at our Schaumburg facility. We do not use extrusions or imported pulley stock. Pick your material, tooth profile, and any number of teeth and we will produce it.

Find us at our location or contact us via phone or email:

Illinois Pulley & Gear

611 Lunt Ave. Unit C

Schaumburg IL, 60193

847-407-9595

sales@ipgbiz.com